PRODUCTION NOTES

Complex Cover Finishing & Precise Registration

The Challenge

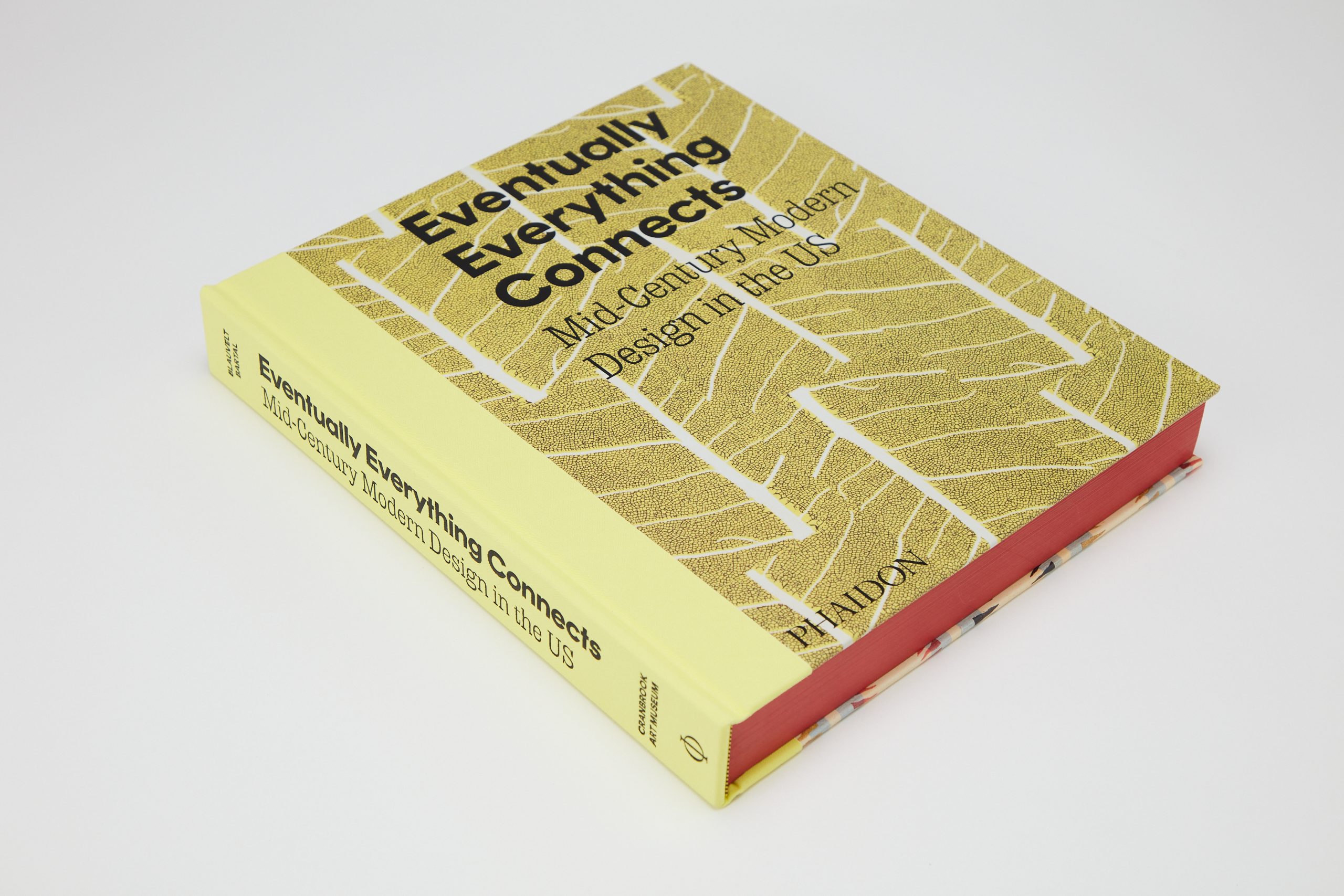

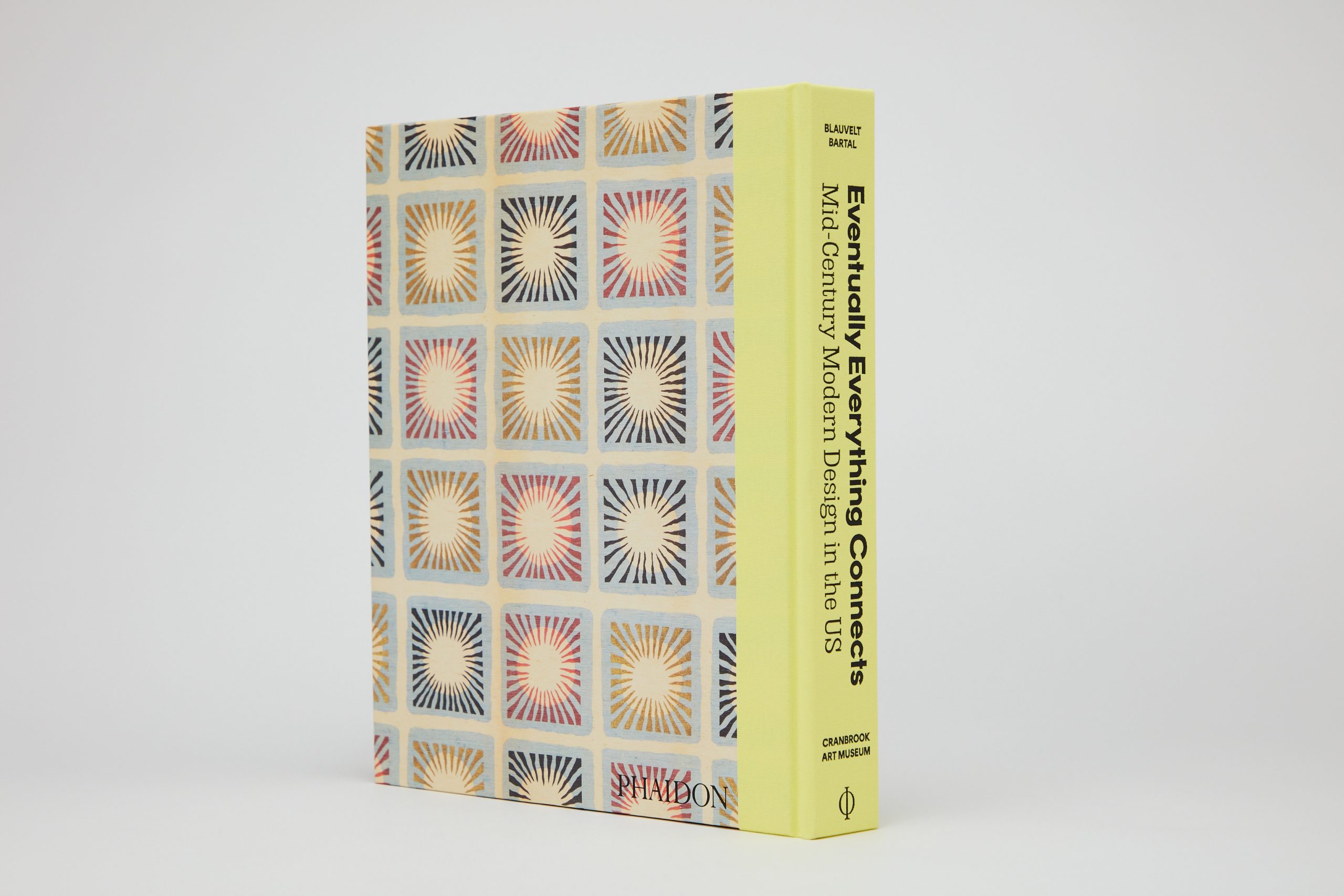

he cover production involves a complex combination of 4-color printing, full-area matte varnish, foil stamping (Deep Blue), and debossing over printed text.

- Registration Risk: The debossed text must align perfectly with the cover's crease line (flap edge). The instruction highlights that the head, foot, spine, and fore-edge all contain bleed images ("dead color positions"). Any slight deviation in die-cutting or pressure will result in visible white edges or structural defects.

- Foil Quality: Previous feedback indicated that foil stamping on small text at the spine was prone to breaking/incomplete transfer.

Our Solution

- Strict Standard Adherence: We will strictly follow the signed "cover test sample" as the absolute reference for all finishing processes to ensure the foil and debossing effects match the client's expectations.

- Precision Control: We will utilize high-precision die-cutting and stamping equipment. Operators are instructed to specifically monitor the alignment between the debossed text and the crease line to ensure they are flush, while carefully managing the bleed areas to prevent any exposure of the paper color.

- Process Improvement: To address the foil breakage on the spine, we will ensure the stamping is solid and intact during the bulk run, likely through optimized pressure/temperature settings.

Color Management on Special Paper

The Challenge

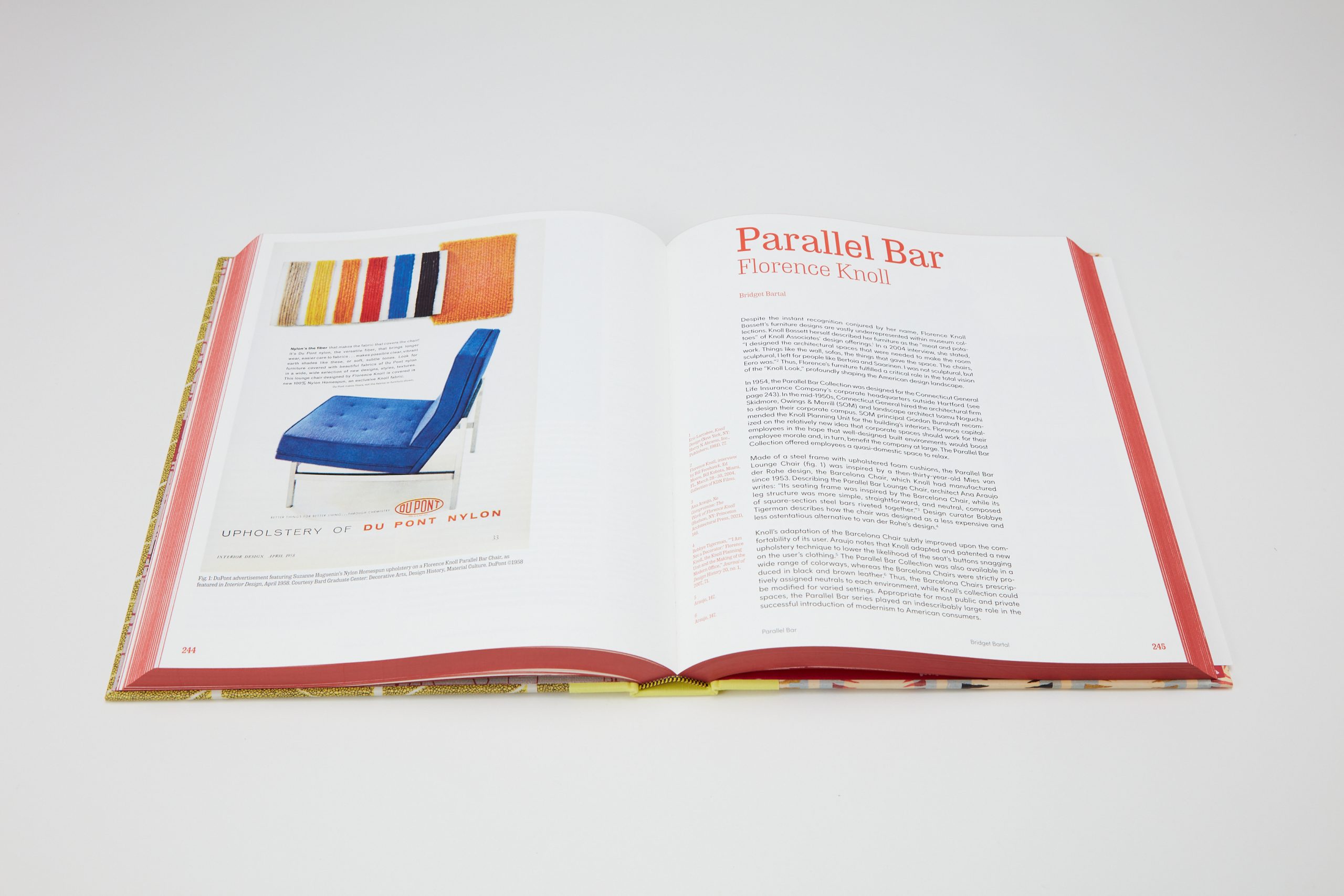

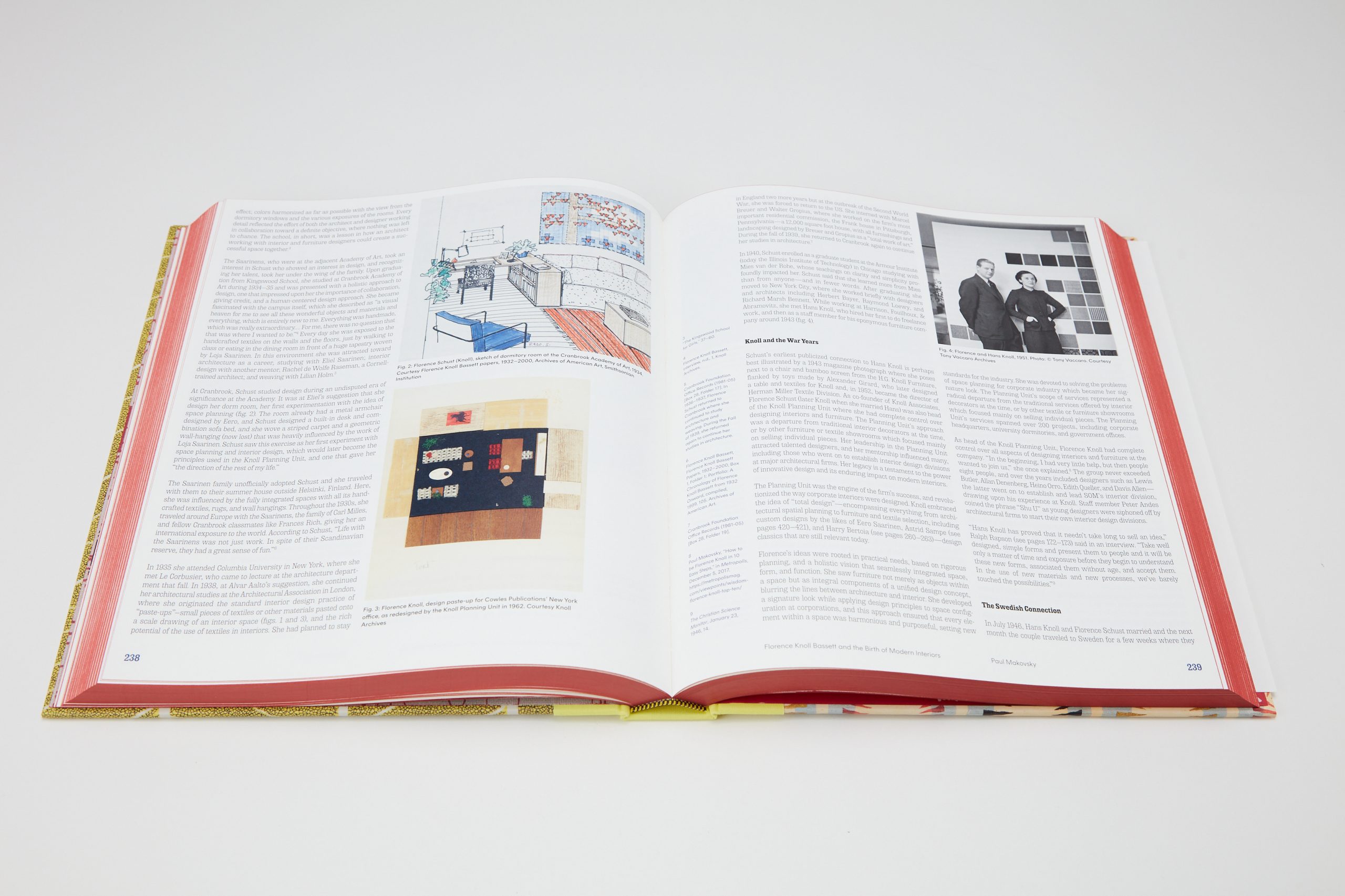

The interior text is printed on 120g special cream uncoated paper (FSC Mixed Credit).

- Color Mismatch: The client’s digital files do not match the natural color of this specific paper, creating a risk of significant color deviation.

- Moiré Risk: Specific image signatures in the text are flagged as being prone to generating Moiré patterns (interference patterns) during printing.

Our Solution

- Customized Color Control: Instead of relying on the client's digital files, we will generate an internal "imposition digital proof" calibrated to the specific paper stock to serve as the reference standard.

- Expert Supervision: A senior printing technician is assigned to personally supervise the press run for both the cover and text to ensure color consistency, particularly for pages with the same background color.

- Defect Prevention: We will proactively monitor the specific signatures for Moiré patterns and make necessary adjustments (e.g., screen angles) to prevent them.

Critical Layout Tolerances and Assembly Logic

The Challenge

The layout design features text positioned extremely close to the fore-edge.

- Cutting Risk: Any fluctuation in folding or thread sewing could cause this text to be trimmed off or misaligned.

- Assembly Sequence: A barcode sticker must be manually applied to a precise coordinate (20mm from spine, 15mm from bottom) on the back cover before the individual book is shrink-wrapped. Previous samples missed this step.

Our Solution

- High-Precision Binding: We will set the folding and sewing machines to higher precision standards for the affected signatures (1-18), with operators conducting frequent checks to ensure the text remains within the safe zone.

- Strict Process Sequencing: The production workflow will be enforced to ensure the "Sticker Application" station precedes the "Shrink Wrapping" station.

- Quality Check: A check will be implemented to verify the sticker’s exact coordinates on the back cover before the unit enters the packaging line.