PRODUCTION NOTES

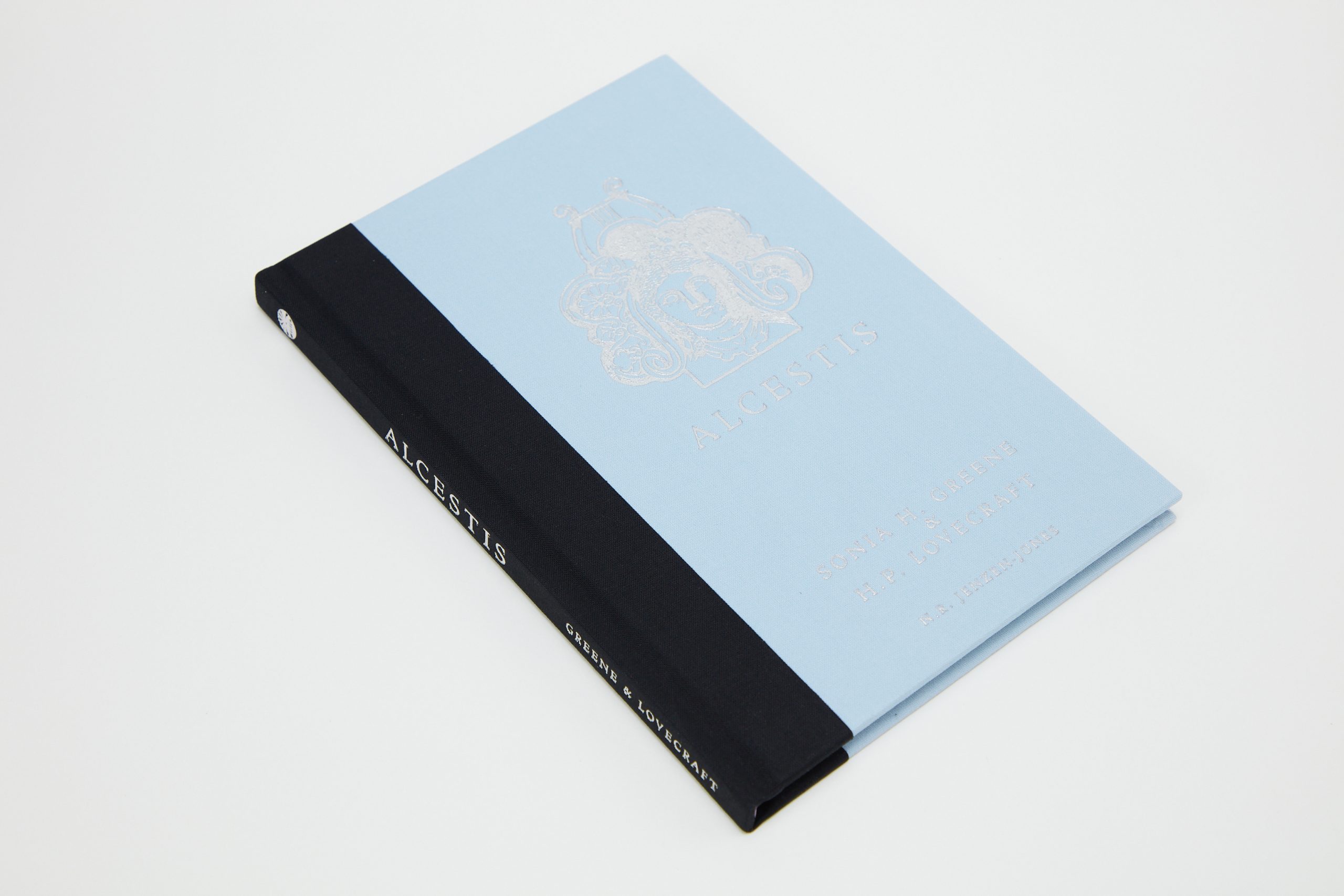

Process Control for Special Binding Structure

The Challenge

The project explicitly requires the binding method to be "Round Back, Tight Back. Unlike the standard hollow back, the tight back structure requires the spine board to fully adhere to the back of the book block, presenting significant technical difficulties:

- Flexibility Risk: If the adhesive application is too thick or the glue texture is too rigid, it will severely affect the fluidity of page-turning and the opening angle of the book.

- Wrinkling and Deformation Risk: During the spine rounding process, if the machine pressure is not controlled precisely, the spine material is prone to wrinkling, unevenness, or asymmetrical arcing.

Our Solution

- Adhesive Selection and Testing: We will select a high-elasticity adhesive specifically designed for tight backs (such as PUR or specialized hot melt) to ensure the spine adheres firmly to the book block while maintaining excellent flexibility.

- Precise Parameter Calibration: Based on the thickness of the 120g special uncoated paper, we will finely calibrate the pressure and arc parameters of the rounding machine to ensure the spine is rounded, full, and symmetrical, preventing any structural damage.

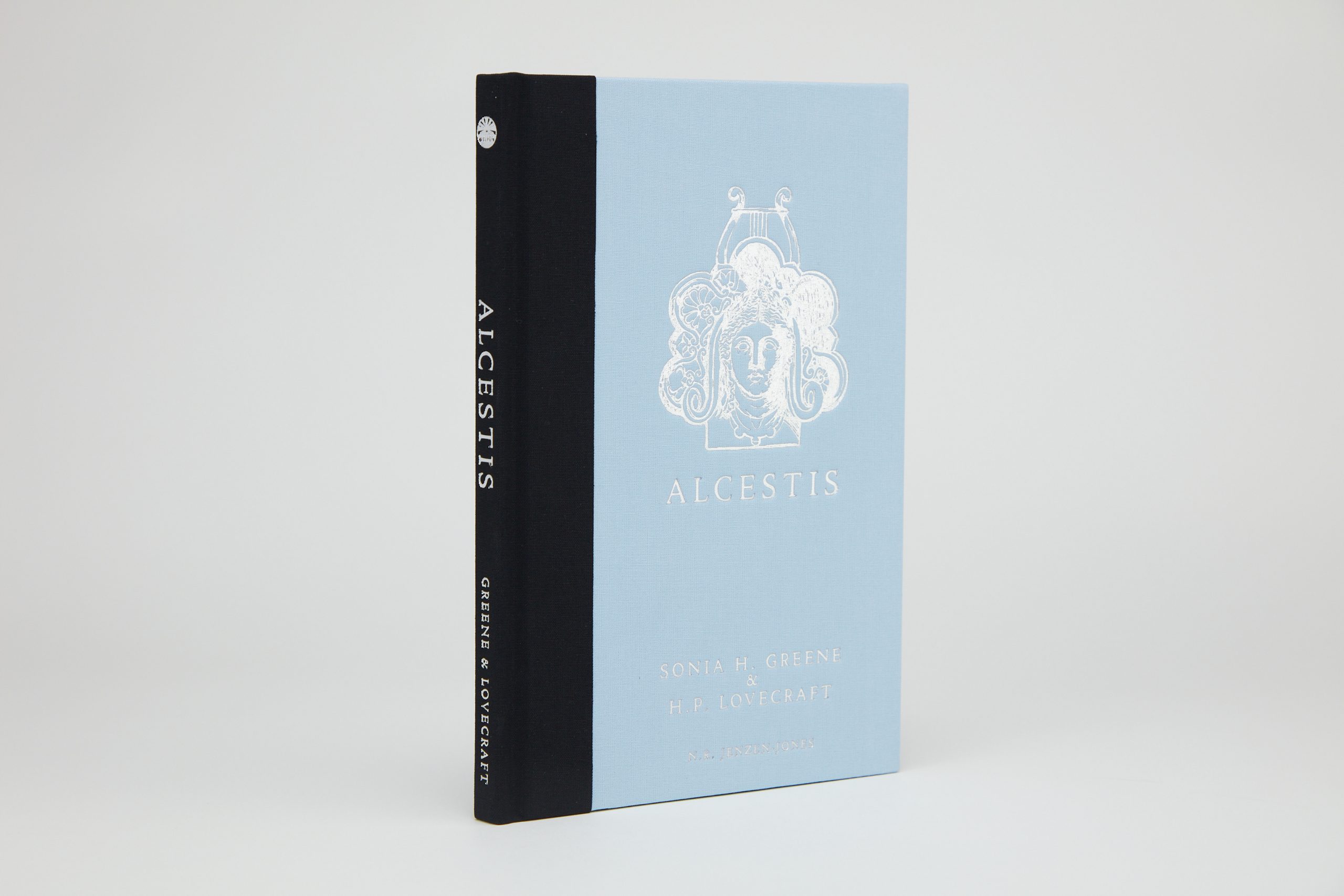

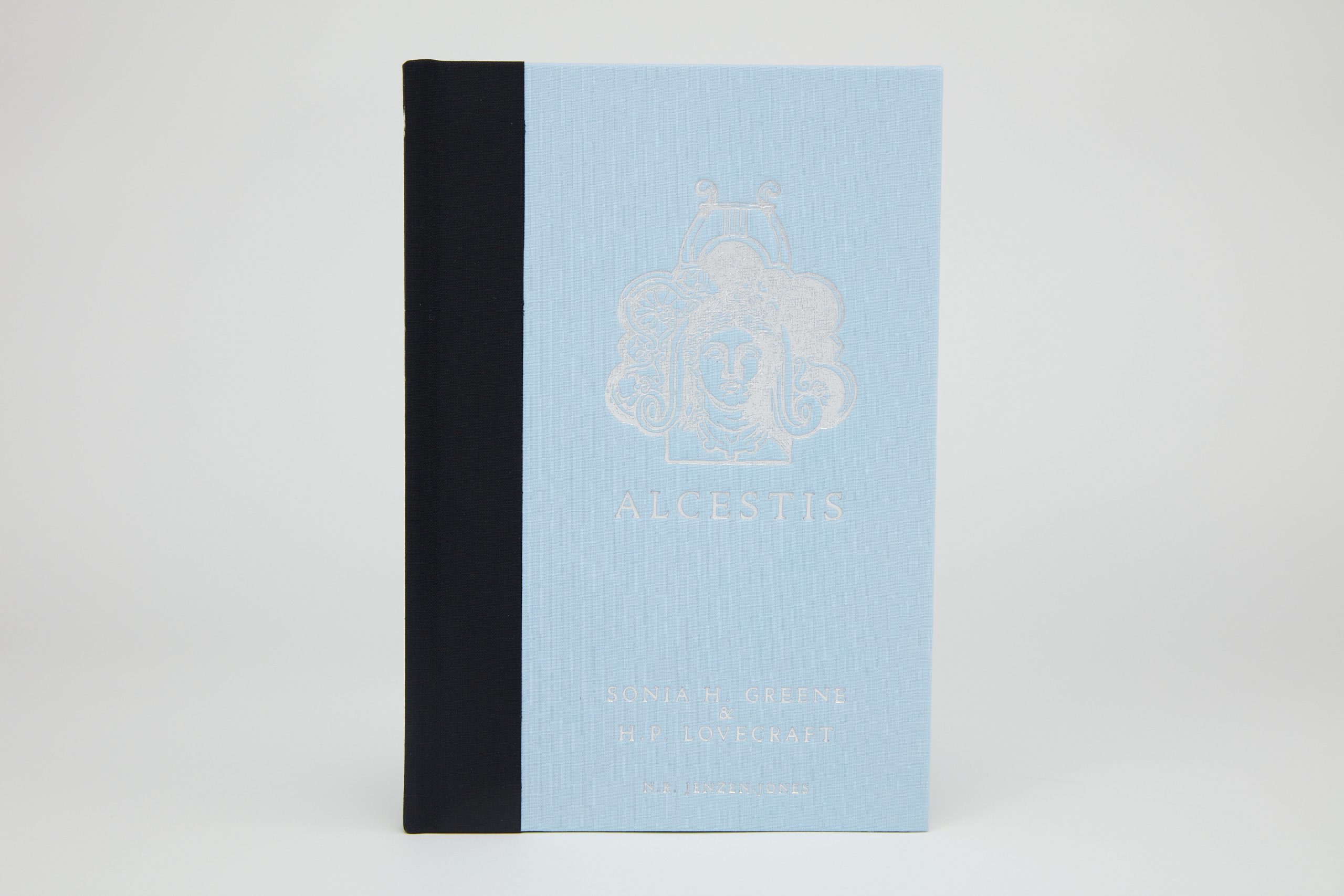

White Foil Stamping on Textured Paper

The Challenge

The cover material selected is a special paper with distinct texture, requiring a "White Foil Stamping" process.

- Insufficient Opacity: Stamping white foil on dark or natural-colored textured paper carries a high risk of show-through (insufficient whiteness), leading to poor visual results.

- Edge Definition Issues: The uneven texture of the paper surface can cause jagged edges, broken lines, or incomplete filling in the stamping, compromising the refinement of fine text.

Our Solution

- Material Matching Test: Before production, we will test different grades of imported white foil to identify the one with the highest opacity and best adhesion for this specific textured paper.

- Temperature and Pressure Optimization: Operators will finely adjust the stamping pressure and dwell time to ensure the foil is fully pressed into the paper grain, guaranteeing a solid fill while preventing blurring caused by excessive pressure.

Registration and Flatness of Spot UV on Dust Jacket

The Challenge

The surface finishing process for the Dust Jacket includes "4-Color Printing + Matte Lamination + Spot UV Varnish.

- Registration Error: The paper is prone to expansion or shrinkage after the high-temperature lamination process, which can easily lead to misalignment between the subsequent Spot UV varnish and the printed image underneath.

- Surface Defect Risk: If the surface tension of the matte lamination is not controlled well, it can lead to defects such as pinholes, cratering, or "orange peel" effects in the UV coating, affecting the high-gloss finish.

Our Solution

- Paper Stability Treatment: The printed sheets will undergo thorough humidity conditioning and balancing both before lamination and before entering the UV process to minimize paper deformation caused by temperature and humidity changes.

- Dyne Level Inspection: We will strictly inspect the dyne level (surface tension) of the matte film surface to ensure its chemical compatibility with the UV varnish, guaranteeing a smooth, mirror-like UV layer without any surface defects.