Production Specs

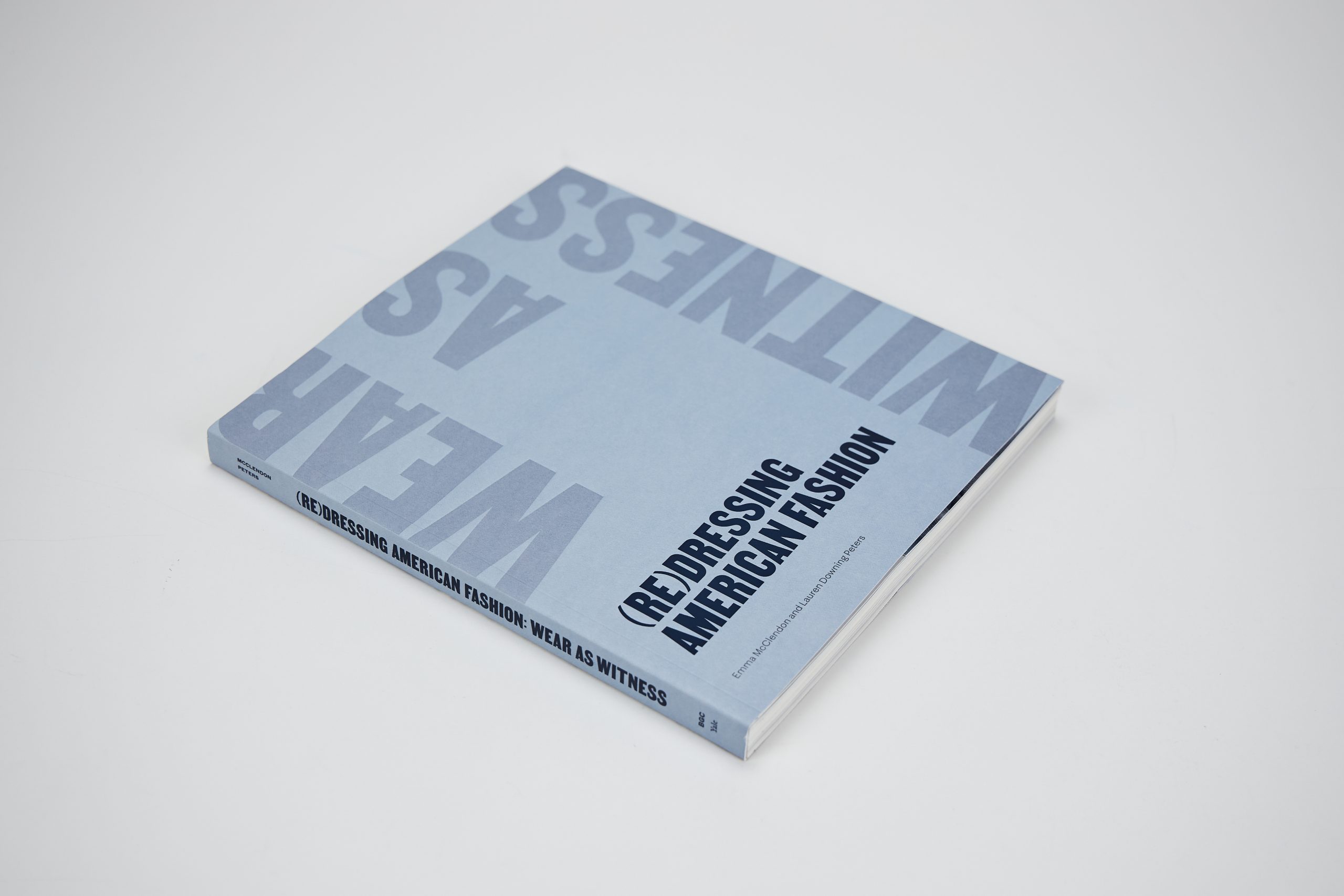

Publisher: BOOKLABS

ISBN: 9780300279160

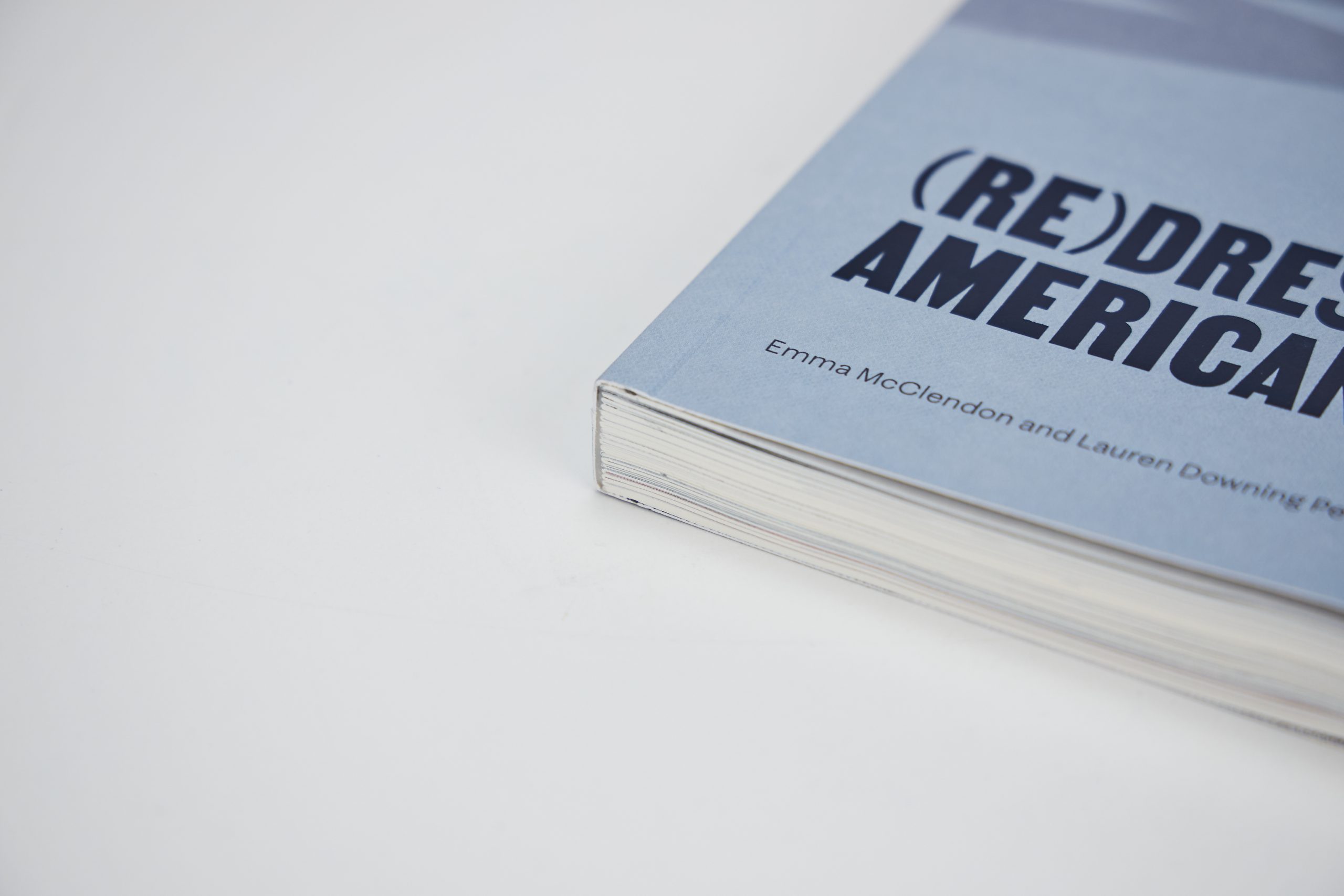

Binding: Section Sewn (Paperback)

Trim Size: 254 x 228.6 mm

Finishing: Gloss varnishing

Cover Stock: 360gsm Oxford Embossed Paper, Extra White, FSC Mix Credit

Interior Stock: 120gsm Woodfree, Cream, FSC Mix Credit

Color Standard/Profile: CMYK / AC2020-Fusion-AM210-Fogra52

PRODUCTION NOTES

Registration and Quality Control for Cover Finishing

The Challenge

The cover involves a combination of processes including double-sided printing, full coating, foil stamping (Dark Blue), and debossing over text.

- Registration Accuracy: The debossed text must align with the cover's crease line (flap area). There are bleed positions at the head, foot, and spine, requiring precise alignment to avoid white edges or structural damage.

- Foil Stamping Quality: Feedback indicated that foil on the spine's small text had previously broken. Production must ensure the foil is solid and intact.

Our Solution

- Parameter Optimization: Adjust temperature and pressure settings for the spine foil stamping and select appropriate foil materials to ensure small text is clear and adheres firmly.

- Precise Alignment: Use the confirmed test sample as the standard to calibrate die-cutting and debossing rules. Operators will monitor the position of the debossed text relative to the crease line to ensure alignment and prevent defects in bleed areas.

- Pre-production Verification: Strictly enforce the "first-piece approval" system, ensuring bulk production matches the signed sample.

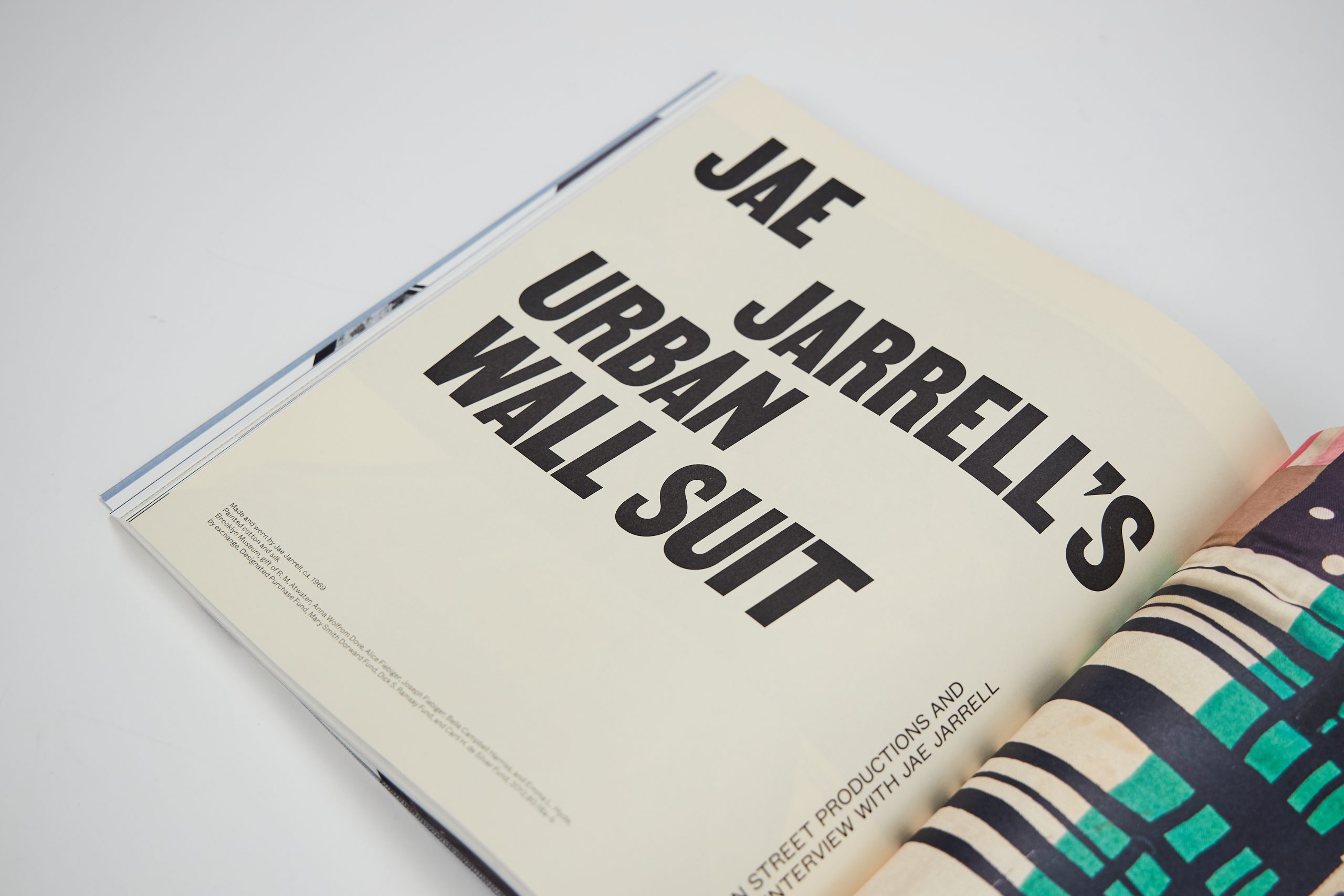

Color Reproduction and Moiré Prevention on Special Paper

The Challenge

The text pages use 120g special uncoated cream paper (FSC certified), which differs from standard coated paper.

- Color Matching: The client's digital file colors do not match the paper's base color. Additionally, consistent printing color is required for pages with the same background.

- Print Defect Risk: The documentation notes a risk of Moiré patterns appearing on images in certain signatures.

Our Solution

- Color Standard Establishment: Instead of following the client's digital file directly, we will use our internal imposition digital proof—adjusted for the paper type—as the reference standard.

- Expert Supervision: A senior technician will supervise the press run for both the cover and text pages. They will monitor ink levels for background consistency and adjust screening angles or pressure to prevent Moiré patterns.

Folding and Binding Precision for Special Layouts

The Challenge

The text layout contains specific design elements, particularly on pages 8 and 10, where text is positioned near the fore-edge. Any deviation in folding or thread sewing could result in this text being cut off or misaligned during the final trimming process.

Our Solution

- Folding Control: The folding process (Signatures 1-18) is designated as a critical control point. We will calibrate the folding knives to ensure the fold line is centered.

- Process Inspection: We will increase the frequency of spot checks from folding to thread sewing, specifically verifying the placement of the text near the edge. A secondary check will be performed before casing-in to ensure the text position is within tolerance.